पॉलीथीन कोटिंग सेवाएं

उत्पाद विवरण:

उत्पाद वर्णन

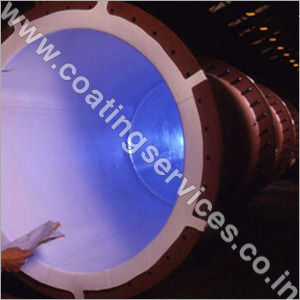

Holding a highly reputed and trusted market standing, we are engaged in offering Polyethylene Coating सेवाएं. These coating services provide a thin film, high gloss finish with exceptional weathering performance characteristics. Commonly referred to as poly coating, this coating is used in virtually all industrial markets to provide a smooth durable finish to a product. The coated product exhibits superior resistance to corrosion, abrasion, and chemical exposure. Polyethylene Coating सेवाएं can be provided without exhibiting degradation in stress crack resistance or thermal stability. These services are best for metal and urethane coatings as well as for fasteners and other metal products.

Durable Protection for Industrial Assets

Polyethylene coatings offer robust protection for a variety of substrates including metal, steel, iron, and concrete. With excellent corrosion resistance and temperature tolerance up to 80C, this coating significantly extends the life of pipelines, tanks, valves, and fittings, making it ideal for demanding industrial and commercial environments.

Flexible Application with Custom Options

Choose from standard or custom color options to meet your projects aesthetic and functional requirements. Our dip and spray coating processes, combined with sandblasting or degreasing surface preparation, ensure outstanding adhesion and a sleek, glossy finish. सेवाएं are available throughout India and tailored to customer specifications.

FAQs of Polyethylene Coating सेवाएं:

Q: How is the surface prepared before polyethylene coating is applied?

A: The surface undergoes sandblasting or degreasing to create ideal conditions for strong adhesion of the polyethylene coating. This process helps remove impurities, ensuring a long-lasting, durable bond and optimal protective performance.Q: What are the main benefits of using polyethylene coatings on industrial equipment?

A: Polyethylene coatings deliver excellent corrosion resistance, strong adhesion, and protection against harsh environments. The smooth and glossy finish enhances the appearance, while the coating extends the lifespan of industrial equipment by shielding it from moisture and chemicals.Q: What application methods are used for polyethylene coatings?

A: Our services utilize both dip coating and spray coating methods. The choice depends on the substrate, size, and desired finish, ensuring a uniform coating thickness between 100 and 1000 microns across all surfaces.Q: Where can polyethylene coating services be applied?

A: These coatings are suitable for pipelines, tanks, valves, fittings, and other industrial or commercial components made from metal, steel, iron, or concrete. We provide services throughout India, catering to various sectors in need of protective coatings.Q: What temperature resistance do your polyethylene coatings provide?

A: Our polyethylene coatings are engineered to withstand temperatures up to 80C, maintaining integrity and performance under typical industrial and commercial operating conditions.Q: Can customers request custom colors for the coatings?

A: Yes, we offer both standard and custom color options so clients can match their specific requirements or brand schemes. Please discuss your preferences with our team during the consultation.Q: When is polyethylene coating ideal for industrial equipment protection?

A: Polyethylene coating is recommended when superior corrosion resistance, smooth gloss finish, customizable color, and strong adhesion are required, especially in settings that expose materials to moisture or chemicals.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

Coating Service अन्य उत्पाद

|

AAA INDUSTRIES

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese