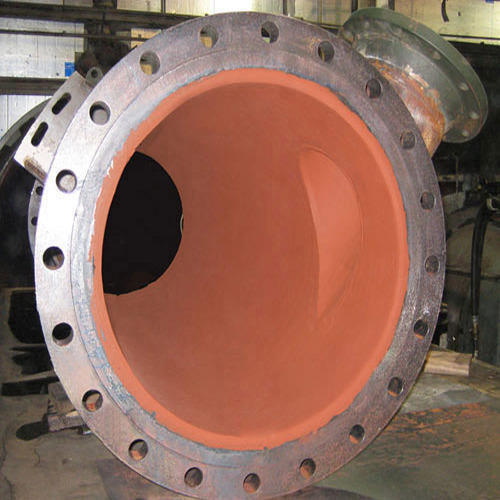

Ptfe Lining Rubber Moulding

Product Details:

- Pressure Resistance Up to 20 bar

- Type PTFE lined rubber gasket/moulding

- Vaccum Range Full vacuum to positive pressure

- Working Temperature -20C to +200C

- Standard ASTM, DIN, or as per customer requirement

- Temperature Resistance Up to 200C

- Gasket Coefficient 0.080.12

- Click to View more

X

Ptfe Lining Rubber Moulding Product Specifications

- ASTM, DIN, or as per customer requirement

- -20C to +200C

- Up to 200C

- Full vacuum to positive pressure

- PTFE lined rubber gasket/moulding

- Up to 20 bar

- Compression moulding and PTFE lining process

- Chemical industry, pharmaceutical, food processing, and corrosive media containment

- PTFE lining

- 6575 Shore A

- Rubber moulded

- PTFE (Polytetrafluoroethylene) lined with high-quality Rubber

- Acid, alkali, solvents, gases, and water

- Round (custom shapes available)

- 320 mm (customizable)

- 0.080.12

Product Description

Capitalise on the outstanding performance of our PTFE Lining Rubber Moulding, designed for first-class chemical resistance and unmatched durability. This cost-effective solution features rarefied white PTFE with black rubber (custom colours available) and supports a wide size range (DN 15 to DN 500, or tailored to your needs). Enjoy excellent abrasion resistance, smooth non-stick finish, and superior sealing for zero leakage. The robust design, optional reinforcement, and long operational lifespan ensure reliable performance even under extreme conditions, up to 200C and 20 bar. Ideal for promotion by distributors, exporters, and manufacturers across Indias industrial markets.

Versatility and Application Scope

Ptfe Lining Rubber Moulding offers a smooth, non-stick surface suitable for aggressive chemical, pharmaceutical, and food processing environments. Its outstanding application across pipe flanges and containment systems delivers exceptional chemical and abrasion resistance. It is used for sealing, leak prevention, and secure handling of acids, alkalis, solvents, gases, and water. This product suits both new installations and retrofitting of existing pipelines, providing a tailored fit for various shapes and sizes as required.

Market Reach and Sample Availability

A sample of our PTFE Lining Rubber Moulding can be handed over for evaluation, helping clients assess its rare qualities firsthand. With a stable domestic mar, it is widely supplied throughout India and exported to diverse international markets. There is no initial charge for standard sample requests. Our distribution network spans manufacturers, service providers, exporters, importers, and traders, ensuring premium access for wholesalers and end-users alike.

Versatility and Application Scope

Ptfe Lining Rubber Moulding offers a smooth, non-stick surface suitable for aggressive chemical, pharmaceutical, and food processing environments. Its outstanding application across pipe flanges and containment systems delivers exceptional chemical and abrasion resistance. It is used for sealing, leak prevention, and secure handling of acids, alkalis, solvents, gases, and water. This product suits both new installations and retrofitting of existing pipelines, providing a tailored fit for various shapes and sizes as required.

Market Reach and Sample Availability

A sample of our PTFE Lining Rubber Moulding can be handed over for evaluation, helping clients assess its rare qualities firsthand. With a stable domestic mar, it is widely supplied throughout India and exported to diverse international markets. There is no initial charge for standard sample requests. Our distribution network spans manufacturers, service providers, exporters, importers, and traders, ensuring premium access for wholesalers and end-users alike.

FAQs of Ptfe Lining Rubber Moulding:

Q: How does PTFE Lining Rubber Moulding benefit industrial applications?

A: PTFE Lining Rubber Moulding provides exceptional chemical and abrasion resistance, ensuring outstanding durability and zero leakage in demanding environments such as chemical processing, pharmaceuticals, and food industries.Q: What is the process for customizing the size or colour of the PTFE lining?

A: Custom sizes and colours can be requested during the ordering process. Our team utilizes advanced compression moulding and PTFE lining techniques to meet specific application requirements and standards.Q: When should I choose PTFE Lined Rubber Mouldings over conventional gaskets?

A: PTFE Lined Rubber Mouldings are ideal when operating conditions demand superior chemical resistance, non-stick properties, and zero leakage, especially where standard gaskets may fail under aggressive media or high temperatures.Q: Where can PTFE Lining Rubber Moulding be installed?

A: This product is suitable for any pipeline system that uses standard piping flanges and handles corrosive or high-temperature media, commonly found in chemical, pharmaceutical, and food processing facilities.Q: What is the recommended usage procedure for optimal sealing performance?

A: Ensure proper alignment of the PTFE lining on the flange surface and use standard installation practices. For complex shapes or operational pressures, optional reinforcement may be applied for added integrity and lifespan.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Rubber Gaskets' category

|

AAA INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese